Here you will find answers to frequently asked questions about

3D laser scanning. In case you have an additional question or if

you can't find the answer to your questions: Please feel free to contact

us!

Hardware

How accurate are the measurements?

For the medium-range scanners: A quick answer is less than a

millimeter to a centimeter. Depending on the type of scanner, each

point has a standard deviation. We can achieve higher accuracy by

executing more scans.

How are the point clouds colored?

An internal digital camera or an extra high-resolution digital

camera takes pictures which can be merged into a 360 ° panorama

image. Subsequently, each point of the point cloud is colored in

accordance with the picture.

Can you work in a specific coordinate system?

We can work in a local system or an international system (WGS84,

LB72, ...). If requested we measure the ground control points with

GNSS (Global Navigation Satellite System which also includes GPS,

Glonass,...).

In industrial plants we normally use the local system of the

customer.

Are 3D laser scanning points as good as points measured with

total stations?

These are just the same but with the advantage that they are

much more, as if it were a 3D photo shape.

Software

How big are the files?

The original scan files are quickly several gigabytes, but once

they are processed the size depends of the data format and the size

of the project.

What are the most common data formats?

PTS files for laser data and LAS files for LIDAR data are the

most commonly used formats for transferring the data. Other common

formats are LAZ, ASCII and POD.

What is LASER?

A laser (Light Amplification by Stimulated Emission of

Radiation) is a device that generates light making use of a very

narrow band of the electromagnetic spectrum.

How does a 3D laser scanner work?

A laser scanner is a device that sends light pulses at high

speed under a changing vertical and horizontal angle until the

entire visible surface is covered over 360 °. For each pulse, the

distance between the scanner and the object being measured is

calculated by determining the elapsed time the difference between

outputted and received pulse.

What is a phase scanner? And a pulse scanner?

Both are time-based laser scanners: they measure the time

difference between transmission and reception.

The time measurement of a phase scanner is realized by emitting

a continuously modulated laser beam and by measuring the phase

difference between the transmitted and the received pulse.

A pulse laser beam scanner does not transmit continuously, but

transmits a short laser pulses which is then reflected by the

object. The time between the transmitted pulse and the received

pulse is recorded.

What are the products that you can create with a 3D laser

scanner?

Points Clouds, digital color orthophotos, volume calculations,

models of civilian objects such as bridges and buildings,

animations, views and cross-sections of buildings,…

What is noise?

If someone passes in front of the scanner or if something moves

during scanning this is also recorded. These non-relevant points

are subsequently cleared by the processing software. A phase

scanner also gets more noise as the distance to the object to be

scanned increases.

How long does a 3D laser scan take?

Depending on the type of scanner and the set or requested

resolution it takes 5 minutes to 15 minutes with a phase scanner

and a half hour to an hour with a pulse scanner. For most projects,

the laser scanner is installed in different places to minimize

shadows or occlusions. The larger and more complex the object to be

scanned, the more set-ups are needed.

Is 3D laser scanning more expensive than a traditional

surveying intervention?

This depends on the complexity. For a simple project, the

traditional surveying intervention remains cheaper. In projects

where safety, response time (shutdown of machines), complexity

(pipes, …) plays an important role 3D laser scanning is often the

most suitable technique.

Can you combine scan data with other data?

Certainly. We regularly compare existing 2D and 3D measurements

with scan data. The combination of scan data of 3D laser scanning,

mobile mapping and airborne Lidar is also possible.

Is a scanner dangerous for the people in the surroundings?

No. The laser beam from the scanner is not harmful to the human

eye. Teccon is VCA** certified and makes safety plans for 3D laser

projects.

Why can only be scanned in dry weather conditions?

Raindrops and mist cause ghostpoints and refraction of the laser

beam.

What are ghostpoints?

Ghostpoints are points where an incorrect distance was recorded

during the gathering, which causes the point to appear in the wrong

place in the point cloud. These points are usually removed from the

point cloud.

What is refraction of a laser beam?

The deflection or 'breaking' of the laser beam when it goes from

one transparent medium to the other. In rain or fog it is about the

transition from air to water. Due to the deflection the laser

signal is lost or an incorrect measurement is made.

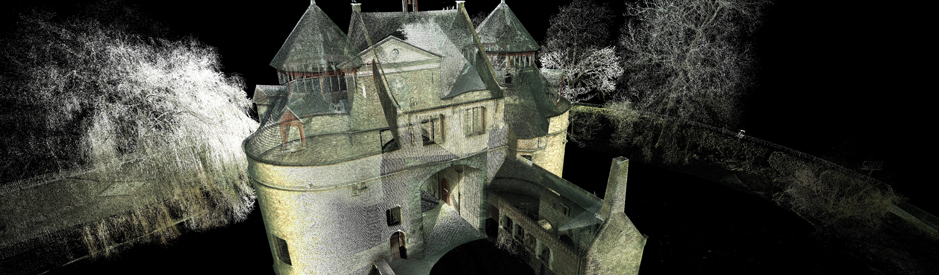

3D Laser scanning of the Ezelpoort in Bruges

3D Laser scanning of the Ezelpoort in Bruges

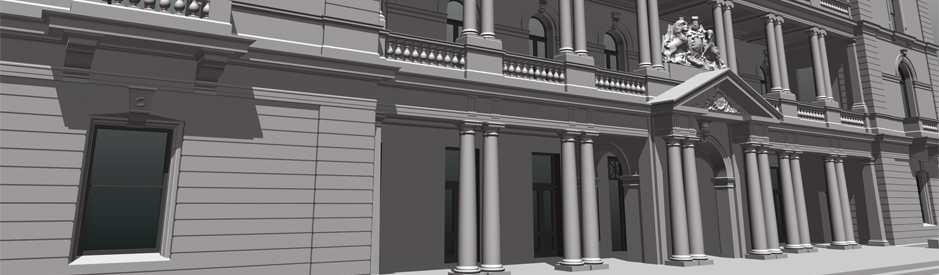

3D model of the customs office in Sydney

3D model of the customs office in Sydney

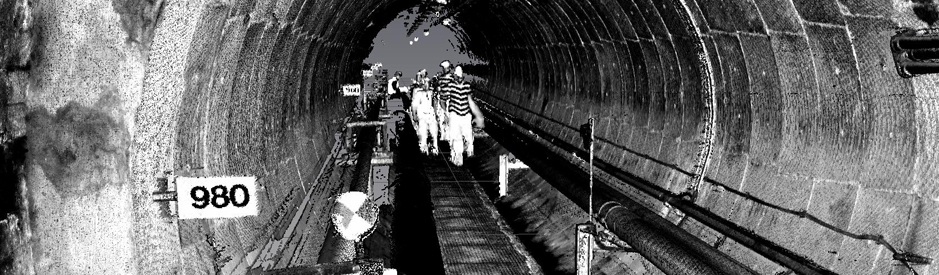

3D Laser scanning off the PALL tunnel

3D Laser scanning off the PALL tunnel

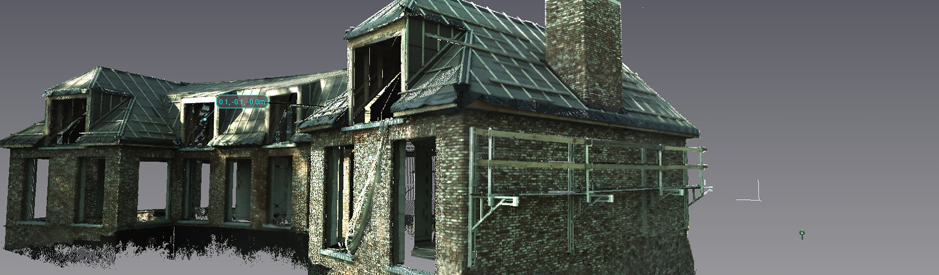

3D Laser scanning of a villa

3D Laser scanning of a villa

3D laserscanning of an historical building

3D laserscanning of an historical building